Review Superpro Front Sway Bar Kit for Mk7gti

For sharper steering, improve treatment and more grip in all driving atmospheric condition.

SuperPro Sway Bars are manufactured, designed and tested right here in Australia. Our Sway Bar range was designed post-obit the idea of 'Dynamic Control'. This resulted in the Sway Bars being engineered to give the vehicle sharper steering, better treatment and more grip, improving your overall driving experience while maintaining safety. Our SuperPro Sway Bar kits add together durability, reliability and better operation outcomes.

| | |

The SuperPro sway bar range includes:

- Heavy Duty 4x4 Sway Bar Kits

- Performance Sway Bar Kits

- Passenger Sway Bar Kits

- Adaptable Sway Bar Kits

- Lite Hollow Sway Bar Kits

- Roll centre correction products

- Caster, camber, toe alignment kits

- Anti-elevator products

SuperPro sway bar kits add durability, reliability and ameliorate performance outcome compared to stock/OEM and other aftermarket solutions.

Heavy Duty 4x4 Sway Bar Kits

SuperPro has a large range of aftermarket 4X4 Sway Bars that accept been in the global marketplace for years. Made in Australia, incorporating years of engineering science experience, development fourth dimension, and meticulous testing, we can safely say that our SuperPro 4X4 Sway Bars are the best. Our Heavy Duty 4X4 Sway Bars provides your vehicle with an increased grip, better handling, and a more precise driving experience on and off road.

Duel Cab Utes such as the Toyota Hilux and the Mitsubishi Triton do not accept Sway Bars included in their design because OE manufacturers did not intend for their vehicles to be used how they currently are. Here at SuperPro, nosotros understand you may take to tow or carry heavy loads for work or on your 4X4 gamble. Without these vehicles having a sway bar, our team recognized that carrying heavy loads caused poor turning capability, alignment issues and less tyre grip both on and off route.

After meticulous research and testing, SuperPro identified that a Sway Bar was the solution required to resolve these alignment and prophylactic problems. Calculation our expertly designed SuperPro Sway Bar to the rear of the vehicle dramatically transformed the Dual Cab Ute range from a utility vehicle to a safe, well rounded driving platform.

Performance Sway Bar Kits

The SuperPro Operation Sway Bar range is used in a variety of vehicles, particularly those used for operation such as track and operation vehicle enthusiasts. A wide range of functioning Sway Bars take been engineered to give the driver sharper steering, amend treatment and more grip on the route and on the runway.

SuperPro Performance Sway Bars are designed to reduce the body gyre of the vehicle, through the increment in stiffness of the bars. This results in the vehicle having a greater balance and a better cornering grip in all performance driving situations. Our Sway Bars correct under and oversteering tendencies and are perfectly balanced for optimum neutral steering handling with a precise turning response. The SuperPro Operation Sway Bars have been designed and rigorously tested by our expert suspension engineers and performance driving professionals to ensure they will give your vehicle the ultimate driving feel.

Passenger Sway Bar Kits

We accept a large range of Sway Confined that are specifically designed for passenger vehicles. These Sway Confined have been engineered to right your vehicles driving geometry and resolve steering issues.

SuperPro Torsional Axle Axle Sway Bars

SuperPro has redefined the manner Sway Bars are fitted to a front bicycle drive vehicle with a Torsional Beam rear axle. These vehicles suffer from inherent understeer, SuperPro Command Bars neutralize the understeer and raise the treatment and stability of the vehicle. With the new subclass blueprint, the benefits of a Sway Bar have never been easier to enjoy!

Features

- New Design Bracket than bolts direct to the lower leap seat

- Sway Bar bolt to the plate with two stage aligning

- No D-Bushes, no clamping to the Torsional Beams

Benefits

- Dramatically reduces rear end torso roll equally there is no original sway bar.

- Corrects the inherent understeer

- Will never come loose or rattle

Why use sway bars, stabilizer confined or anti-roll bars?

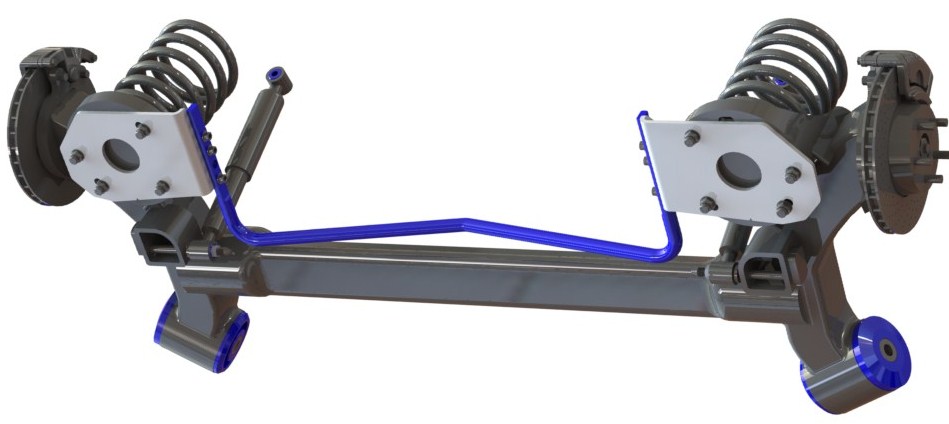

In that location are many reasons why your vehicle should be enhanced with our SuperPro Sway Bars. The prime reason a bar is fitted onto a vehicle is to maintain maximum tyre contact with the road. Suspension systems are engineered to vary the angle of the wheel and contact patch as a vehicle travels along the road. The optimum contact patch is achieved when the cycle is in a vertical position. Braking, body coil, squat and swoop all crusade the shift in contact patch.

SuperPros superior manufacturing and technological expertise in intermission ensures your vehicle has swell performance and guarantees safety when cornering. SuperPro Sway Bars work by ensuring the load of your vehicle is distributed evenly over your tyres. This delivers longer tyre life and a better grip on the road leading to a more comfortable driving feel.

Types of Superpro Sway Bars

Adjustable sway bars

SuperPro’s adjustable Sway Confined permit you command the rigidity of the bars past assuasive yous to accommodate the length of the arms. The adjustable Sway Bars are designed with two, 3 or 4 different points of adjustment providing you with numerous stiffness options to better suit your driving needs. These Sway Bars also reduce the need to replace the entyre Sway Bar.

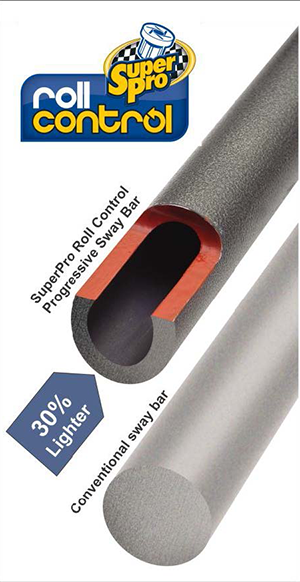

Hollow sway bars

SuperPro has particularly designed hollow Sway Confined which are upward to 30% lighter than traditional bars and are fabricated from race spec chromoly. These unique progressive design Gyre Control Bars are fully adjustable and provide reduced weight and better fuel efficiency for a range of vehicles. Our hollow Sway Bars facilitate progressive performance characteristics with even more than sophisticated tuning and interruption setups.

Why offer an selection of tubular sway confined?

For the last decade, manufacturers have focused a bully bargain on reducing vehicle mass to lesson fuel consumption. This has led to researching solutions that include more effective lightweight metals. Through the research and careful pick of pick of materials, hollow Sway Bars were deemed every bit an constructive solution.

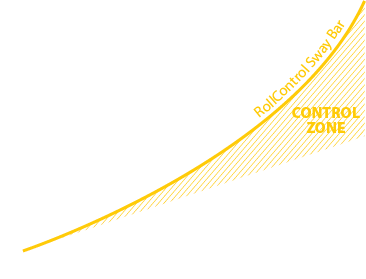

How is a Sway Bar stiffened?

A Sway Bar operates in a cross-sectional plane, offer torsional resistance to twist. Simply making a Sway Bar thicker makes the torsional resistance greater and therefore the Sway Bar becomes stiffer. Tubular material operates exactly like a solid bar using cross section torsional resistance. With a tubular Sway Bar design, Sway Bar rate or resistance can exist adjusted by changing both the outside diameter and wall thickness.

Vehicles Covered

SuperPro sway bars are bachelor for a massive range of vehicles, both as replacement and upgrade solutions for passenger, 4x4 and performance vehicles.

The all-time mode to find if we take a sway bar for your car is to utilize our website product search!

SuperPro Sway Bar Engineering science and Manufacturing

SuperPro employs 2 methods for manufacturing Sway Confined. I method is to bend Sway Confined using precision CNC machines. The other method is purposed for custom Sway Bar kits, which are hand aptitude by our team of expert product engineers.

The principal method SuperPro utilizes is CNC bending because this offers our SuperPro team greater consistency and speed while maintaining platonic results. The degree of bends and length of bends is programed into the automobile, resulting in precise production of our Sway Bars.

Although SuperPro uses high quality spring steel, there is a lot of work that goes into bending the metallic. When the bars are bent, information technology volition spring back into shape, wanting to return to its original state. The SuperPro engineering team have meticulously researched exactly how to counteract this issue for each bend, giving an extremely accurate Sway Bar blueprint. Our SuperPro Sway Confined offer all vehicles an enhancement and greater performance.

- SuperPro 4WD sway bar Kits are made from reinforced Australian bound steel.

- SuperPro Functioning sway bar kits are fabricated from performance leap steel.

- SuperPro custom sway bar Kits are hand bent for custom applications and practice not warrant mass product.

Setting aligning on arms

SuperPro adjustable Sway Confined take their adjustment levels determined based on the vehicle application. For accurate results, our SuperPro engineering team has developed a set of unique precision stamping tools and dies used to set the aligning holes at the end of the Sway Confined.

Sand Blasted and Powder Coated

All SuperPro Sway Bars become through a three-stride powder coating process. The initial stage of sand diggings is the Primer, this offers an anti-rust layer and removes any impurities on the metal. The second step is to utilize an initial powder glaze to the Sway Bar. This footstep is imperative to the process as it helps adhere the anti-rust primer previously applied and helps the last stage of blanket. The last footstep of the process is to powder coat the Sway Bars in a blue coating and put them in an industrial oven to bake. This gives our Sway Confined our signature SuperPro chrome blueish terminate and offers increased protection with over 1mm of powder coating.

SuperPro Sway Bar Process

- Review the vehicle & assemble data

- If a sway bar exists, replicate and improve original design

- Sample test sway bars are produced and used for further product testing

- Last Sway bar is precision modeled

- Virtual testing is conducted

- Real world testing is conducted

- Sway Bar is certified and is given to manufactory for production

Visit Tradeview to find the correct SuperPro sway bar products for your motorcar

Source: https://www.superpro.com.au/products/sway-bars

0 Response to "Review Superpro Front Sway Bar Kit for Mk7gti"

Post a Comment